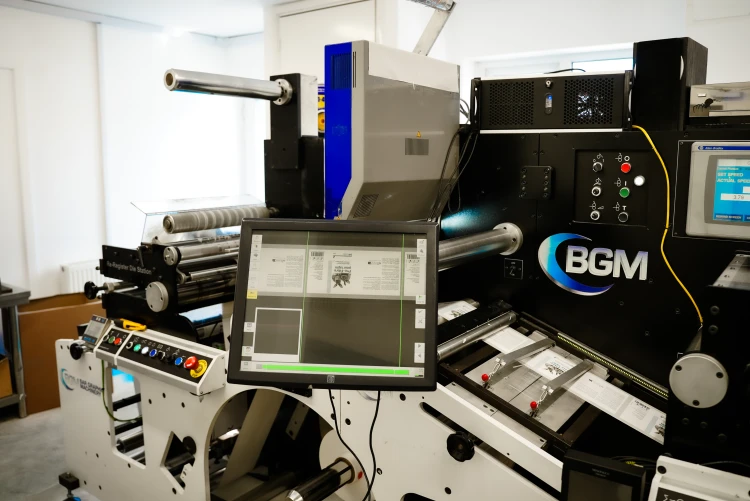

NIKKA - Automatic label inspection system

Compares deviations like colour change register and die-cutter movement. When the deviation exceeds the set tolerance the machine stops and shows the operator the position of the defect.

100% full web camera inspection

Detects print errors at speeds up to 320m/min

Compares against a known good image of each label or previous good job

The ALIS system detects typical print faults like colour change, broken/missing text, ink spots, register change and missing labels

EyeC Proofiler

The EyeC Proofiler combines the power of intelligent software with the performance of a high-resolution scanner. The inspection system digitally compares the scanned samples against the signed-off proof (typically a PDF file).

Ultra fast process.

Automatically scans the first print against the approved PDF proof.

100% inspection.

Identifies all major defects such as colour variation, mis-register and text clarity.